How Industrial Scales Enhance Safety and Precision in Bulk Weighing Applications

Why to Choose Industrial Scales for Accurate Weight Measurement in Different Industries

In a period where precision is paramount, the selection of industrial scales for accurate weight measurement plays an essential role across diverse markets. These ranges not just enhance operational efficiency but likewise make certain compliance with governing criteria, affecting whatever from manufacturing to shipping. Their durable design and advanced modern technology accommodate numerous applications, strengthening the need for meticulous weight management. Understanding the subtleties of these scales is important for any type of company intending to enhance processes and minimize pricey errors. The concern remains: what specific aspects should one take into consideration when picking the right range for their special operational requirements?

Relevance of Accurate Weight Measurement

In the realm of industrial operations, the significance of accurate weight measurement can not be overstated. Accurate weight dimension is foundational across various industries, affecting both operational efficiency and product top quality - Industrial Scales. It works as a vital aspect in stock management, ensuring that materials are appropriately represented, therefore decreasing waste and reducing costs

In production, exact weight measurement directly impacts production processes. Abnormalities in weight can lead to substandard items or extreme source allowance, affecting total productivity. Furthermore, in sectors such as drugs and food manufacturing, adherence to rigorous weight requirements is vital for regulative compliance and consumer safety and security.

Furthermore, exact weight measurements facilitate efficient logistics and supply chain management. Properly evaluated deliveries make certain that transport expenses are enhanced which supply levels are preserved precisely, thereby protecting against stock shortages or overstock circumstances.

Kinds Of Industrial Scales

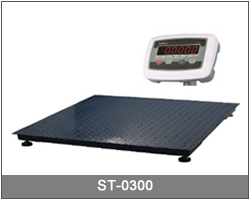

A wide range of industrial scales are offered, each created to fulfill certain measurement needs throughout varied sectors. Usual types include flooring scales, which are robust and ideal for weighing huge products or pallets in storehouses and circulation centers. Bench scales are smaller and ideal for lighter products, commonly used in retail settings or producing for specific portion control.

One more category is mobile ranges, which supply the versatility to be moved easily around work sites, making them excellent for field operations or momentary configurations. Precision scales, on the various other hand, are designed for high precision and are frequently used in laboratories and quality control settings.

Tons cells are important components in numerous commercial scales, transforming push into an electric signal for precise analyses. In addition, truck scales provide the ways to weigh heavy automobiles and their tons, guaranteeing compliance with guidelines and maximizing logistics.

Last but not least, checkweighers automatically compare the weight of items against pre-programmed limits, improving quality control in production lines (Industrial Scales). Each type of commercial scale offers an one-of-a-kind function, satisfying the details demands of markets such as manufacturing, logistics, food processing, and drugs

Advantages of Utilizing Industrial Scales

Constantly utilizing industrial ranges provides substantial advantages across various sectors. Among the primary benefits is improved precision in weight dimension, which is important for preserving high quality criteria and regulatory compliance. Exact dimensions prevent pricey errors in shipping, production, and stock monitoring, eventually bring about increased operational efficiency.

Additionally, commercial ranges are designed for longevity and robustness, enabling them to endure severe atmospheres commonly found in manufacturing and warehousing. This durability ensures a lengthy lifespan, reducing the requirement for constant replacements and maintenance expenses.

Additionally, utilizing industrial scales improves security and reduces waste. By making sure that items are evaluated precisely, business can stay clear of overloading vehicles, which can bring about crashes and fines.

Applications Across Numerous Industries

Industrial ranges play a critical duty in countless fields, consisting of production, logistics, food processing, and pharmaceuticals. In production, these scales are essential for ensuring that resources are determined precisely, thus maintaining item quality and uniformity (Industrial Scales). Precision in weight dimension straight affects production effectiveness and cost management

In logistics, commercial scales promote the precise weighing of deliveries, which is crucial for sticking to optimizing and delivering guidelines freight expenses. Accurate weight data helps simplify operations and boosts supply chain management.

The food processing sector relies greatly on commercial scales for compliance with wellness and safety and security policies. They are made use of to weigh components exactly, ensuring that formulas satisfy both high quality standards and lawful requirements. This is necessary not only for customer safety yet additionally for maintaining brand integrity.

Pharmaceutical companies make use of commercial ranges to guarantee precise dosages in medicine manufacturing, where also the tiniest variance can have substantial consequences. Conformity with rigorous regulative criteria makes precise weight dimension essential in this industry.

When Choosing Ranges,## Elements to Think About.

Picking the right range for specific applications requires careful consideration of a number of aspects. First and foremost, the capacity of the range is crucial; it should fit the maximum weight of the items being measured without exceeding its limits. Additionally, the readability, useful site or tiniest increment the range can properly present, is crucial for precision, specifically in industries where weight discrepancies can lead to substantial economic losses or safety concerns.

Environmental conditions likewise play a significant duty in range selection. Scales used in moist or corrosive environments might need specialized products to make sure durability. Transportability may be essential in particular applications, necessitating battery-operated and light-weight models.

Verdict

In verdict, the selection of industrial ranges is crucial for making sure precise weight dimension throughout diverse markets. Their capacity to offer specific analyses not just boosts functional effectiveness yet also supports regulative conformity and stock Industrial Scales management. The versatility and toughness of these ranges facilitate their application in various industries, inevitably adding to set you back decrease and enhanced product quality. Thus, buying high-quality commercial ranges is crucial for companies aiming to make the most of and maintain high standards productivity.